Search

Focussing towards more sustainable offerings for the construction industry

Jayanta Ray, General Manager – Industrial and OEM, GS Caltex India, speaks on the primary factors that construction equipment customers prioritise when selecting lubricants.

Powering Progress

The article explores the reasons behind the increasing usage of diesel engines in construction equipment, their impact on performance and efficiency, and the technological advancements shaping the future of construction machinery.

India is a critical market for Cummins

Antonio Leitao, Vice President – Off Highway, Engine Business & Europe ABO Leader, Cummins Belgium

R&D is crucial for staying ahead of market trends

Gajanan V Gandhe, Country Lead and Vice President, Dana India Sandeep Khullar, Executive Director, Off Highway & Commercial Vehicle, Dana India

Automation at the Forefront

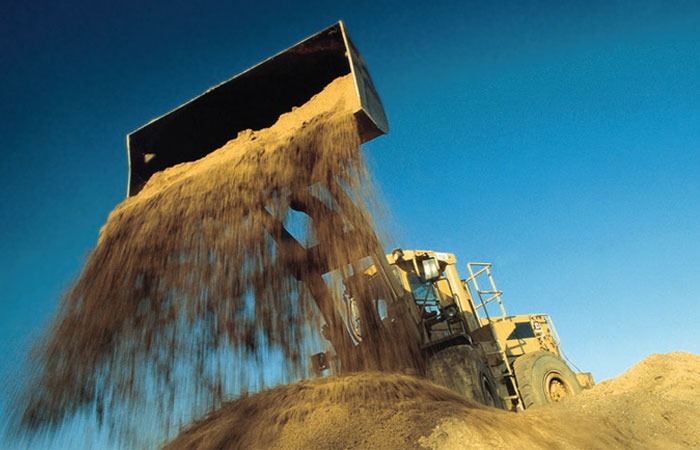

Companies use automated material handling equipment because it increases productivity and reduces waste, which results in significant cost savings.

Heading towards a new high!

After two years of lull, the excavator market should grow again and reach 25,000 units in 2022.

OTR tyre market has bright prospect

India OTR tyre market stood at 11.2 million units in 2021 and forecasted to reach 15 million units by 2023. The market is likely to grow at a CAGR of 9.05 per cent in volume terms.

The demand for off highway tyres is at an all time high

Rajiv Poddar, Jt. MD, BKT Tires

Rajiv Poddar of BKT Tires: Demand for off highway tyres is at an all time high

Rajiv Poddar, Jt. MD, BKT Tires, speaks on the current market size of OTR and industrial tyres, and segments that are driving the demand for these products.

Are IoT & AI just a hype

Trelleborg is currently focusing the Cognitive Sealing approach on industries and applications in which there is a very high cost of downtime and maintenance.

Digital continuity in vehicle using open standards

The automobile industry inclusive of the off highway and mobile machinery are cost sensitive at the same time technology craving industries. To keep pace with technological advancements these industries constantly invest heavily in research and development projects.

OPC UA over TSN – Unified standard for the IIoT

In order to keep pace with technological advancements off-highway and mobile industry constantly invest heavily in research and development projects.

Are IoT & AI just a hype

The internet of things is significantly transforming industries such as automotive, Healthcare & Medical, Energy and Off highway.

We try to produce more in India

Trelleborg India showcased latest sealing solutions such as the Z25 polyurethane seal for high temperature applications in Off Highway segment.

EQUIPMENT INDIA Awards & CEO Forum 2018

After the bitterly cold days and nights of the famed Delhi winter, spring is said to augur good tidings. Or so it is believed. Maybe, it was in continuation of this tradition that the city successfully held yet another edition of the Equipment India Awards.

Foundation of Infrastructure Research Studies Training (FIRST) hosts 5th EQUIPMENT INDIA Annual Awards

The Foundation of Infrastructure Research Studies Training (FIRST) hosted the 5th EQUIPMENT INDIA Annual Awards at Hotel LALIT in New Delhi on Friday 16th February, 2018.

Electric Throttle Actuators

The latest electric throttle actuators provide a cost effective way to control engine speed on mechanical diesel engines. Compact and easily installed, they enable greater freedom of machine design and the use of more ergonomically optimised controls.

Clean Diesel Engines

To begin with, Off Highway Research, a part of KHL group in their half yearly report that in terms of percentage growth, India is expected to be the most buoyant major market in the near-term, with 21 per cent growth forecast this year

Zooming Ahead

Trucks and heavy tractors for cargo haulage and transportation of aggregate materials, coal, overburden from mines, iron ore and other bulk materials, are riding the curve of exponential growth.

Caterpillar Launches New Products and Solutions

Caterpillar announced the launch of its popular B3 series skid steer loader (SSL) in the Indian market at Excon 2015.

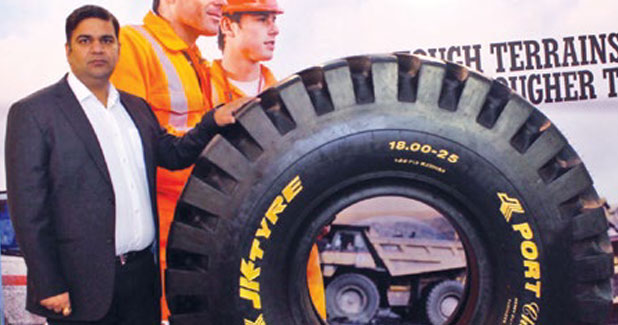

New OTR Tyre for Port and Terminals

JK Tyre has launched the Port Champion OTR tyre for applications in port and terminal segments.

On Course for Success

Bright prospects lie ahead for dumpers, but cost-effective conveyors may pose serious competition in the future, finds Charu Bahri. Industry voices affirm a turnaround has happened in the off highway dumper segment

Caterpillar launches new products and solutions

Caterpillar announced the launch of its popular B3 series skid steer loader (SSL) in the Indian market at Excon 2015.

Exceeding Expectations

According to a report released by ICEMA, the current market size of the construction equipment including backhoe loader, concrete mixers excavator is around $2.8 billion. Further, the Indian construction equipment industry

Optimising Fuel Efficiency

Transmission solutions play a vital role in the overall performance of an equipment. Availability of the latest technologies in transmission solutions have helped OEMs to improve the efficiency level of their equipment.

ZF transmissions are tailor-made for different applications

ZF has recently strengthened its business development footprint for the Indian market through establishing a local engineering resource. Suresh KV, President for ZF in India elaborates on the company?s solutions to the CE industry.

We have been achieving a double-digit growth despite market downturn

Oerlikon?s Drive Systems Segment India is looking to double its turnover to Rs 2,000 crore in five years, says Rajesh Aggarwal, Executive Director, Sales & Marketing, Drive Systems India.

?Bearings? for Long Life

India is set to be one of the biggest manufacturing hubs in the world, within the next few years. What does this entail for the bearing industry? Will ?Make in India? campaign boost the industry? According to Hrishikesh Kulkarni, Business Head - Drives and Off-highway, Industrial Market, SKF India the government?s call for ?Make In India? has sent out positive cues to the global manufacturing community.

Versatility, reliability, durability and unmatched performance excite customer to choose CAT excavators

Traditionally, excavators with operating weight 10 to 24 tonne are classified as medium range and in the last five years, their sales constitute above 70 per cent of the total excavator sales, out of which 20-24 tonne category accounts for approximately 50 per cent and 10-15 tonne is approximately 20 per cent.

Diggies to Scoop the Growth Pie

Market indicators show visible signs of economic recovery and infrastructure development. Crawler excavator segment is expected to witness resurgence in sales from 2015 and is expected to grow to 26 per cent.

Excavators to Dominate

Within the Indian construction equipment industry, the crawler excavator segment is the largest by value and the second largest, after backhoe loaders, in terms of number of units sold.

Multiple taxation regime across states to be streamlined

The Central Government can support in overcoming some of the challenges by speedy implementation of a unified GST, greater investment outlay towards infrastructure development, especially in the off-highway sector, and more thrust in skill development through industry-ready educational programmes/vocational courses, says Abhijit Gupta, Managing Director, Case Construction Equipment India.

+91-22-24193000

+91-22-24193000 Subscriber@ASAPPinfoGlobal.com

Subscriber@ASAPPinfoGlobal.com